Insulation with Hemp Makes Good Sense, If Not Yet Profits

By Trevor Yahn-Grode, Data Analyst, New Frontier Data

Among the many hemp fiber product categories vying for respective footholds among the industrial marketplace are construction materials.

Hempcrete – the much-publicized method of construction using a mixture of hemp hurd and lime – has been praised by advocates for its capacity in carbon sequestration, but the novel construction material faces serious threats to adoption in the U.S., not the least being the mountain of red tape required to change municipal building codes on a county-by-county basis. Furthermore, Hempcrete construction requires contractors to learn almost an entirely new method of home construction, creating a steep learning curve which presents an additional barrier to adoption.

Other hemp-based construction materials face lower barriers to entry, as they can replace existing products and fit into existing construction methodologies without having to invent an entirely new category of construction material. Hemp insulation is one such product.

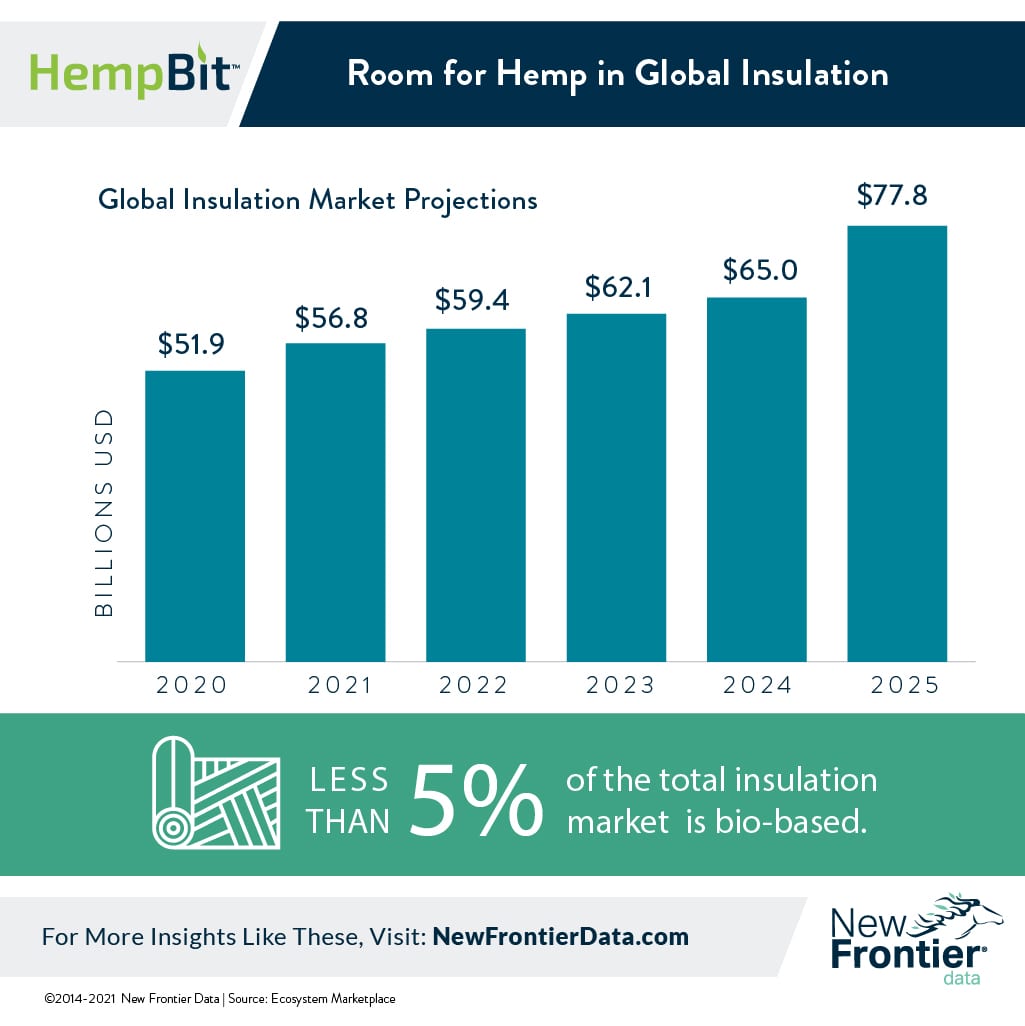

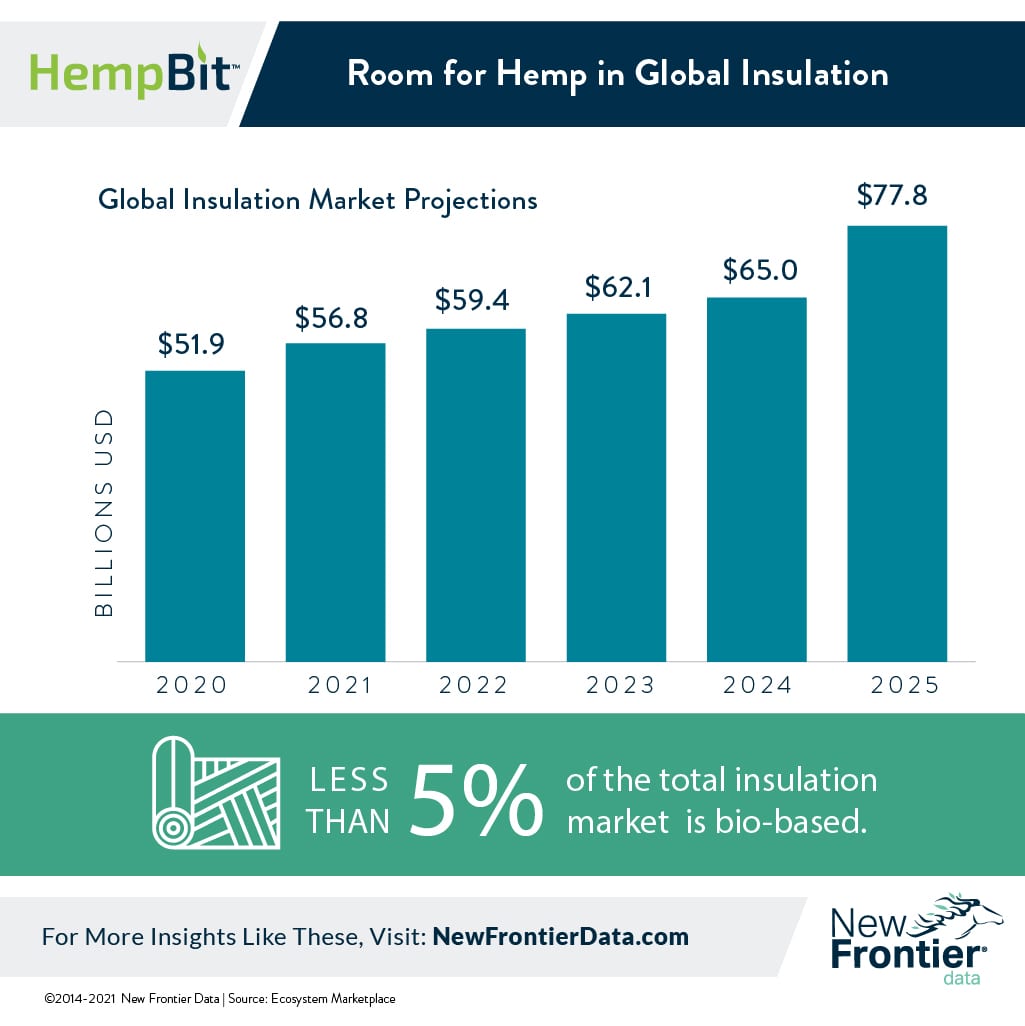

Insulation is necessary in the construction of every residential and commercial structure. In the U.S., it is a $11.4 billion industry, and is forecasted to continue growing over the next five years at a 2.7% compound annual growth rate (CAGR). Growth in the insulation market is part of a thriving construction materials industry that is swelling with development. The immense scale of growth in the construction market represents a unique challenge in light of the industry’s outsized carbon footprint.

The construction and operation of buildings is already responsible for roughly 10% of global CO2e emissions, and projected to more than double over the next half-century – the equivalent of building a new New York City each month.

Fiberglass insulation, especially, possesses a substantial carbon footprint. To manufacture it, molten glass must be heated to 2,500 degrees Fahrenheit, and mixed with chemicals and minerals mined from the earth, an incredibly energy intensive process.

As the construction industry seeks to decarbonize, it is looking to bio-based materials as a possible solution. Bio-based alternatives to traditional insulation materials have already seen significant growth over the past decade, with the cellulose insulation market reaching $2.5 billion in 2020. Despite that growth, bio-based insulation accounts for less than 5% of the total insulation market. Hemp insulation manufacturers are seeking to change this with their products, which they claim can provide the same level of quality as their competitors while maintaining carbon neutrality.

Like most other hemp fiber products currently, however, price remains a major obstacle to growth. Current hemp insulation products cost anywhere from 300%-500% more than their carbon-intensive counterparts, restricting adoption to only the most carbon-conscious consumers. Manufacturers of these materials say that their price will come down as production reaches scale, but are also expecting government climate-policy to help them achieve price parity in the near term, either by subsidizing carbon-neutral construction products, or by making carbon-intensive alternative materials like fiberglass insulation more expensive.

The post Insulation with Hemp Makes Good Sense, If Not Yet Profits appeared first on New Frontier Data.

#CBD #Hemp https://newfrontierdata.com/cannabis-insights/insulation-with-hemp-makes-good-sense-if-not-yet-profits/ June 3, 2021 1:31 pm

#CBD #Hemp https://newfrontierdata.com/cannabis-insights/insulation-with-hemp-makes-good-sense-if-not-yet-profits/ June 3, 2021 1:31 pm